Product Description:

Ceramic Oxide Powder is a versatile product that offers a wide range of applications due to its unique chemical composition and physical properties. This powder is a combination of different ceramic oxides, primarily Al2O3 and TiO2, which play a crucial role in determining its characteristics and performance.

The chemical formula of the Ceramic Oxide Powder includes Al2O3 and TiO2, with varying percentages depending on the specific variant. The most common compositions available are Al2O3-13%TiO2, Al2O3-40%TiO2, and Al2O3-25%TiO2, each offering distinct advantages and suitability for specific uses.

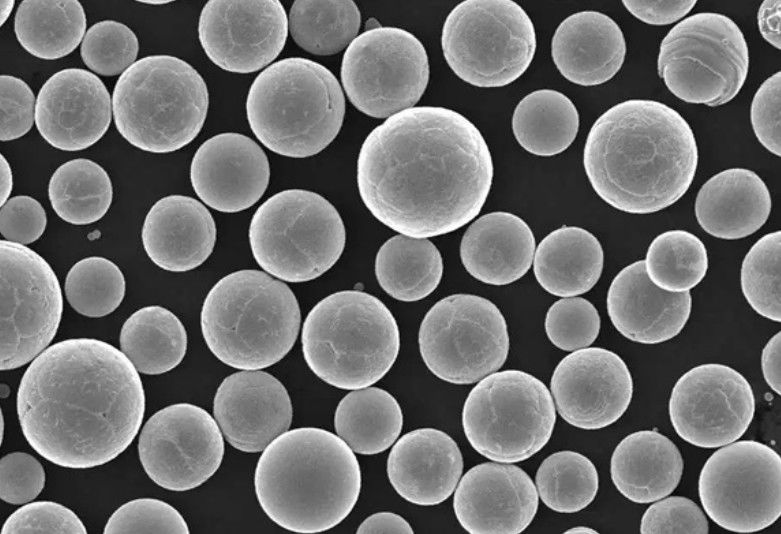

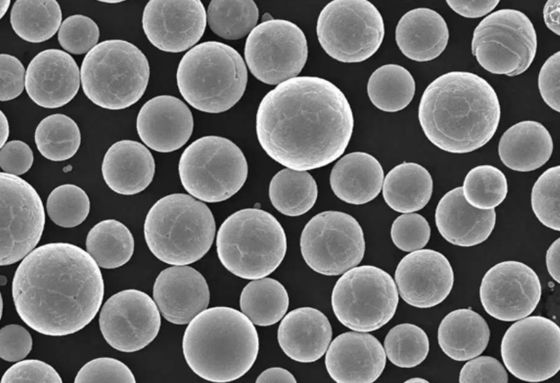

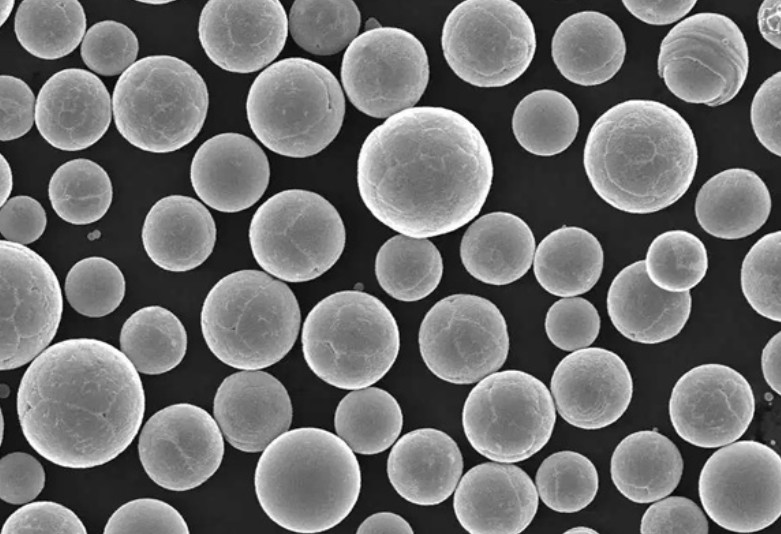

One of the key attributes of Ceramic Oxide Powder is its appearance as a fine powder. This powder is finely ground to achieve a specific particle size distribution, which is crucial for its performance in various applications. The color of the Ceramic Oxide Powder is typically grey, giving it a neutral and versatile aesthetic that blends well with different materials.

One of the essential physical properties of Ceramic Oxide Powder is its melting point, which can vary depending on the specific oxide composition. The melting point is a critical factor to consider when using this powder in high-temperature applications, as it determines the temperature threshold at which the powder will undergo phase transitions.

Particle size is another crucial attribute of Ceramic Oxide Powder, with typical ranges including 45-15um, 38-10um, 25-5um, and so on. The particle size distribution of the powder plays a significant role in its flowability, packing density, and reactivity, making it essential to select the appropriate size range based on the intended application.

The combination of Al2O3 and TiO2 in Ceramic Oxide Powder offers a unique blend of properties that make it suitable for a wide range of applications. The presence of Al2O3 provides excellent mechanical strength, thermal stability, and chemical resistance, making the powder ideal for use in structural ceramics, refractories, and abrasive materials.

On the other hand, TiO2 enhances the optical properties of the Ceramic Oxide Powder, making it valuable for applications requiring high brightness, UV resistance, and color stability. The synergistic effects of Al2O3 and TiO2 create a versatile powder that can be tailored to meet specific performance requirements across various industries.

In summary, Ceramic Oxide Powder is a valuable product with a unique chemical composition, physical properties, and performance characteristics. Whether you need high mechanical strength, thermal stability, optical brightness, or chemical resistance, this powder offers a versatile solution for a wide range of applications. With different compositions, particle sizes, and colors available, Ceramic Oxide Powder can be customized to meet your specific requirements and deliver optimal results in your projects.

Features:

-

Product Name: Ceramic Oxide Powder

-

Applications:

-

Widely Used In Textile Machinery

-

Rolls In Paper Industry

-

Parting Rolls In Chemical Fiber Industry

-

Butterfly Valves In Hydraulic Industry

-

Insulated Bearings

-

Wear Rings

-

Etc.

-

Solubility: Insoluble In Water

-

Melting Point: Varies Depending On The Specific Oxide

-

Appearance: Powder

-

Particle Size: 45-15um、38-10um、25-5um Etc

Technical Parameters:

|

Solubility

|

Insoluble In Water

|

|

Color

|

Grey

|

|

Particle Size

|

45-15um、38-10um、25-5um Etc

|

|

Appearance

|

Powder

|

|

Applications

|

Widely Used In Textile Machinery, Rolls In Paper Industry, Parting Rolls In Chemical Fiber Industry, Butterfly Valves In Hydraulic Industry, Insulated Bearings, Wear Rings, Etc.

|

|

Melting Point

|

Varies Depending On The Specific Oxide

|

|

Chemical Formula

|

Al2O3 ,TiO2

|

Applications:

BODA Ceramic Oxide Powder, model AT, originates from China, and is composed of Al2O3 and TiO2. The powder is grey in color and has a fine appearance in powder form. With a melting point that varies depending on the specific oxide composition, this product offers versatility in different applications.

One of the key applications of BODA Ceramic Oxide Powder is in textile machinery where it can be used for various purposes. The powder's composition of Al2O3-13%TiO2 makes it suitable for use in rolls in the paper industry, providing durability and efficiency in paper processing.

In the chemical fiber industry, the Al2O3-40%TiO2 variant of the powder can be utilized in parting rolls, ensuring smooth operation and longevity of the equipment. Additionally, in the hydraulic industry, the Al2O3-3%TiO2 composition is ideal for butterfly valves due to its strength and resistance to wear and corrosion.

Moreover, BODA Ceramic Oxide Powder can also be applied in insulated bearings and wear rings, offering excellent thermal and mechanical properties. Its grey color and powder form make it easy to incorporate into various manufacturing processes for enhanced performance.

With its wide range of applications in different industries, BODA Ceramic Oxide Powder is a versatile product that meets the diverse needs of textile, paper, chemical fiber, and hydraulic industries. Its unique composition of Al2O3 and TiO2 provides specific properties required for each application, ensuring reliable performance and durability in various scenarios.

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!